Custom Air Cargo Containers

|

|

|

Granger Aerospace has provided a number of industry leading solutions to a number of internationally recognized OEMs and major players in the Aerospace and Defense sectors.

Granger Plastics Company recently formed a new division of Granger Industries, to work closely with a number of its industry leading customers in the Aerospace, Commercial Airlines, Air Cargo Companies and more.

Granger Aerospace Products is committed to excellence and proiding our customers with the highest quality products possible. Granger Plastics Company has provided industry leading Air Cargo Container solutions to the Aerospace and Commercial Airline industries for nearly 20 years now. Granger Industries has produced over 20,000 custom Air Cargo Containers for a number of domestic and international aerospace leaders. With this proven experience, Granger Industries has recently began unveiling a line of patent pending, proprietary, Air Cargo Containers or ULD Containers.

Granger Aerospace Products Air Cargo Containers are the only cargo container produced from a combination of aluminum and durable LLDPE (Linear Low Density Polyethylene). We provide a lower cost alternative to expensive aluminum and polycarbonate containers.

The Granger Aerospace Products, Non-Certified Air Cago Containers are manufactured and tested to current SAE AS1677 Standards (General Requirements for Noncertified Cargo/Baggage Containers).

Our Quality Assurance staff has extensive experience with ULD's and Air Cargo Containers. This experience combined with Granger Plastics previous success of providing Custom Air Cargo Containers for a number of industry leaders, has lead to one of the most durable Air Cargo Containers produced in the world!

The bases of all Granger Aerospace Products features a high quality, light weight 5052 and 6061 T-6 aluminum. Every part is carefully inspected for conformance to Granger Aerospace Products quality standards. The Air Cargo Container base assembly is fastened together using Stainless Steel self-locking screws and nuts for optimal strength and easy removal. Standard on every Granger Aeropace Air Cargo Container, is our unique threshold tube that greatly strengthens the front base edge rail.

The Air Cargo Container body is produced by a manufacturing process called Rotational Molding. The Air Cargo Container body is rotomolded from certified, virgin, prime polyethylene (LLDPE). Using a linear low density polyethylene with a rotational molding process, allows Granger Aerospace to produce a rugged, impact resistant Air Cargo Container body. The Air Cargo Container body is able withstand the harshest weather elements and the roughest of ground handling operations. Each one of our containers is hand assembled in our facility by knowledgeable, skilled employees. At your request; the Air Cargo Container bodies can be molded in virtually any color allowing you to enhance you company’s branding and recognition.

Our doors and nets are constructed from the highest quality materials and is offered in a variety of designs and colors. Whatever the requirement, Granger Aerospace Products has the door designs to fulfill your operations needs.

Custom ULD | Custom Air Cargo Container Features

- • Granger Aerospace Products cargo containers are the only cargo container manufactured from a combination of aluminum and durable LLDPE.

-

• The ULD container body is weld able.

-

• The Granger Aerospace Products Air Cargo Container is lighter than most standard containers.

-

• Granger Aerospace Products Air Cargo Containers are robust.

- • No aluminum body panels to patch.

- • No aluminum body frames to replace.

- • Lighter weight, less down time and lower repair costs equals lower cost of ownership.

- • Enhanced Threshold.

- • Fewer fasteners to replace.

- • Unique design allows for faster repairs.

- • Less spare parts to keep in stock.

- • Granger Aerospace Products offers alternative solutions for your ULD needs.

-

• It is our goal to offer our customer not only lower cost Air Cargo Container but a trusted partnership for your company.

-

• It is our goal to offer more choices to our customers.

-

• Through our focus on technology & research, we are continually making improvements to our design.

-

• Our customers will save fuel by using the robust Granger Aerospace Air Cargo Containers as well as cost-efficient lightweight containers.

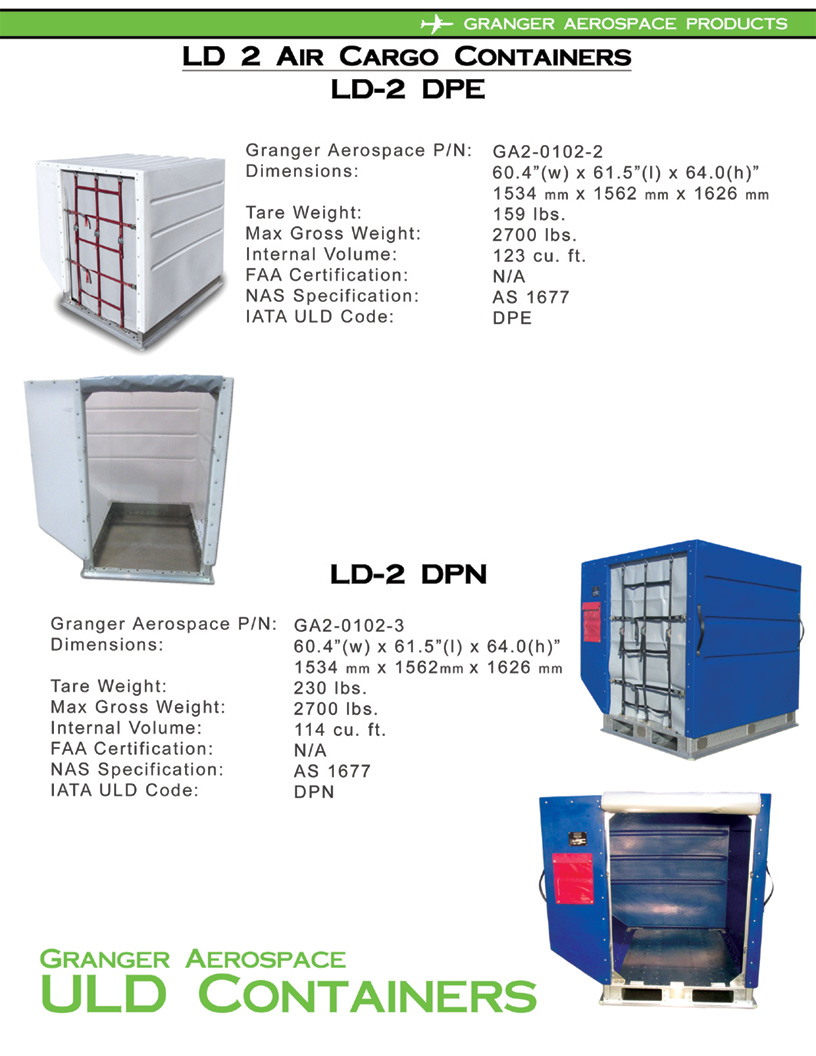

LD 2 DPE/DPN Information

LD 3 AKE/AKN Information

LD 8 DQF/DQN Information